FEATURED PROJECT

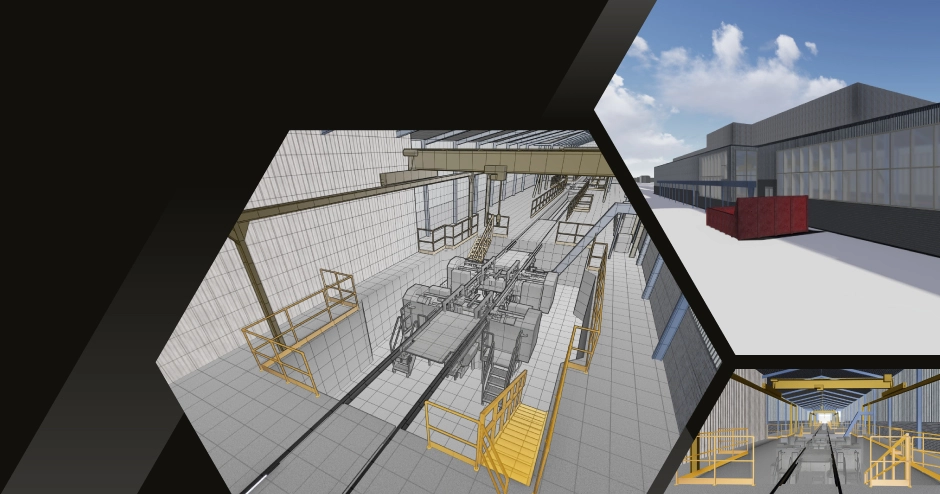

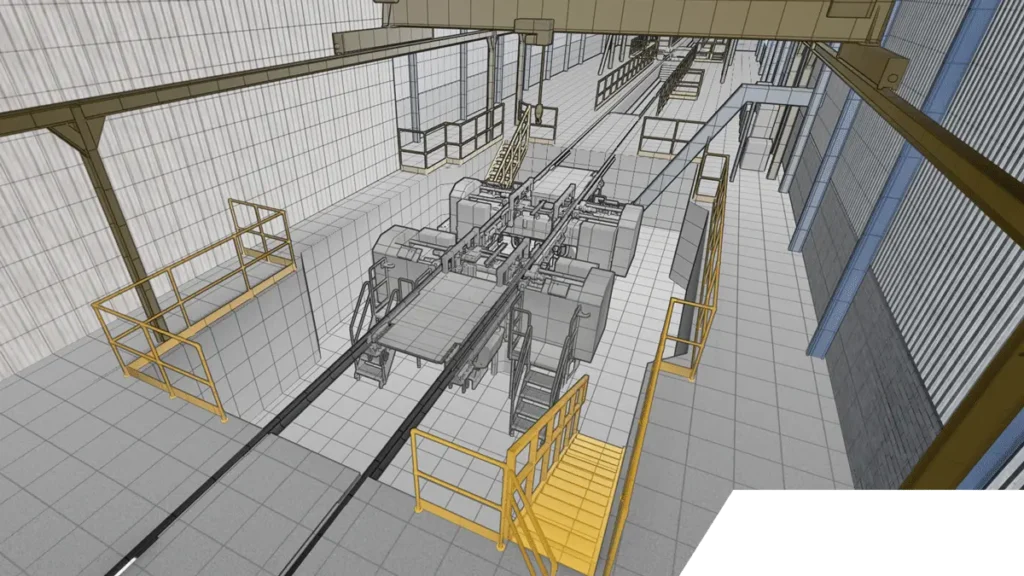

Illford Wheel Lathe Feasibility Study

Design a wagon maintenance hub for maintenance of several wagon fleets

Requirements

The replacement of a life-expired single-headed wheel lathe with a double-headed wheel lathe to lathe 4 & 5 car sets of various rolling stock fleets.

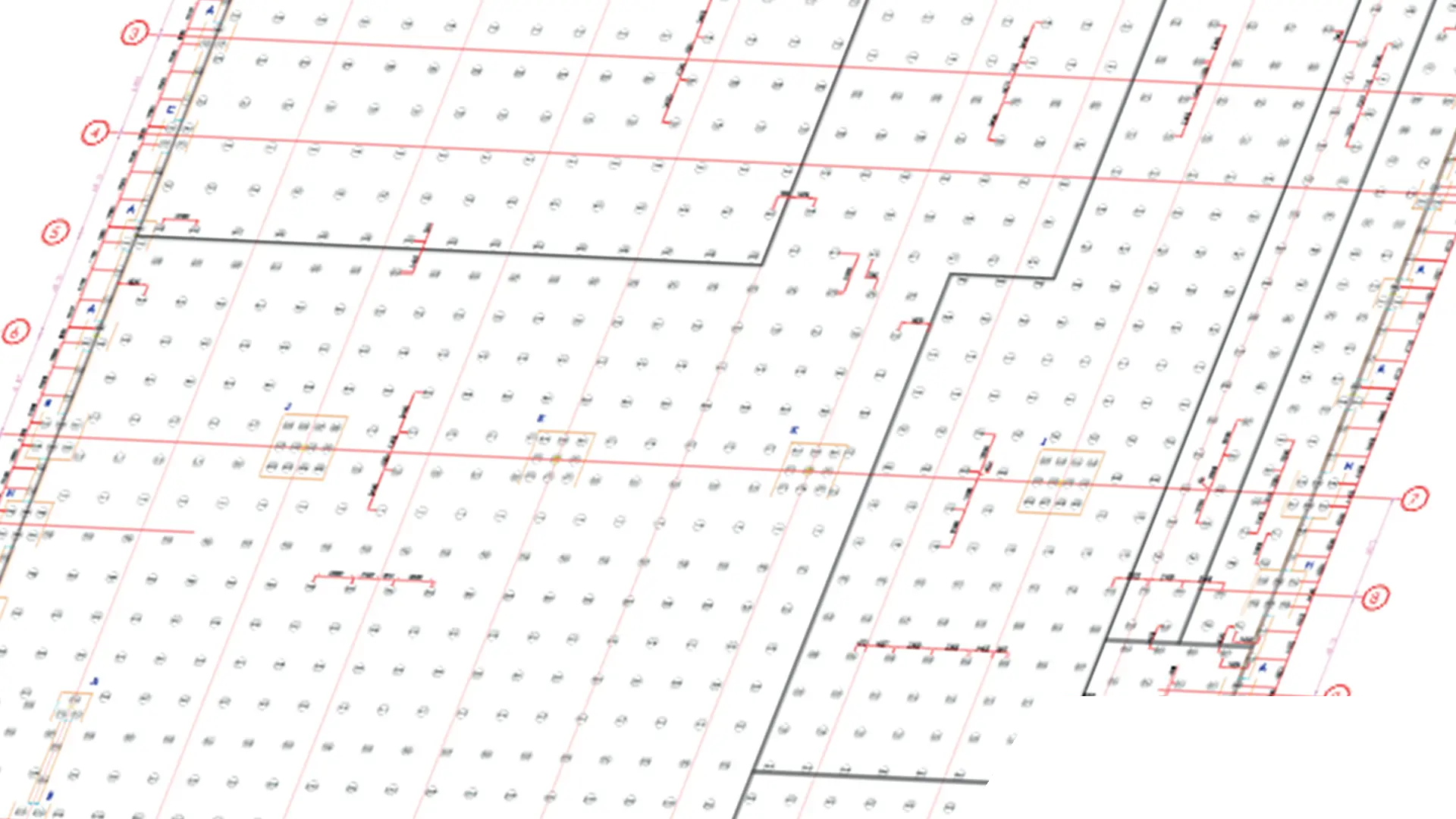

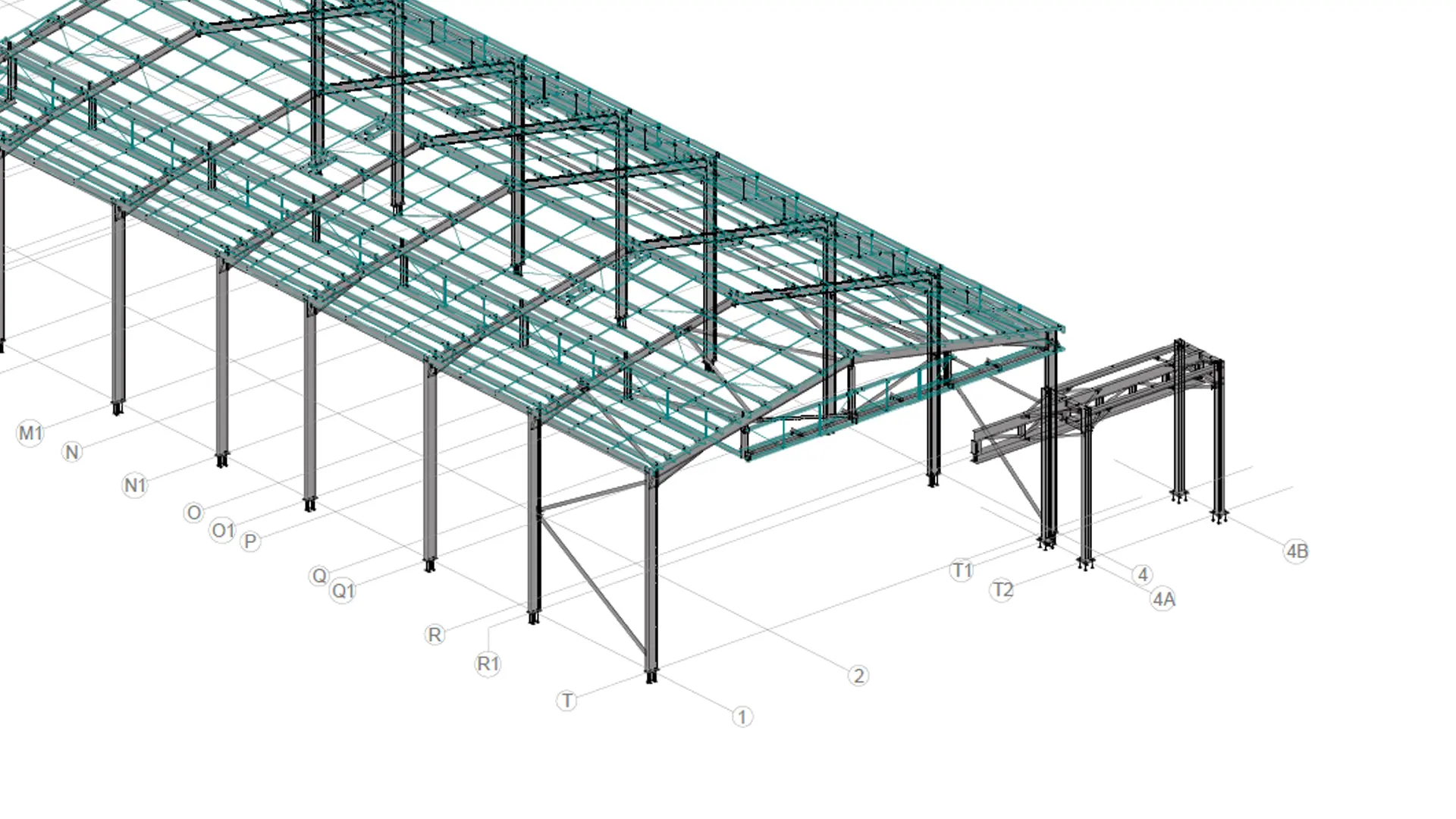

Our consultancy process included optioneering to determine the optimum location of a double-headed wheel lathe, outlining any building, infrastructure, permanent way, foundation, wheel lathe pit, and OLE alterations, clarifying the suitability of the existing crane, and finally, conducting checks on the depots’ existing power supply capacity.

Outcome

- All designs to Network Rail-compliant standards by the GRIP process

- GRP (ground penetrating radar) survey

- Desktop studies for gauging, crane suitability, existing infrastructure dimensions, rolling stock clearances

- Site investigations for condition of building

- Steelwork, concrete pit and permanent way

- Outline drawing production

- Feasibility report

- 3D visualisation and fly through

See more projects

Oldham Column Foundations

Outline and detailed design for foundational stone columns.

Hull Botanic Gardens Superstructure

Rail depot infrastructure upgrades and structural modifications to rail shed building.