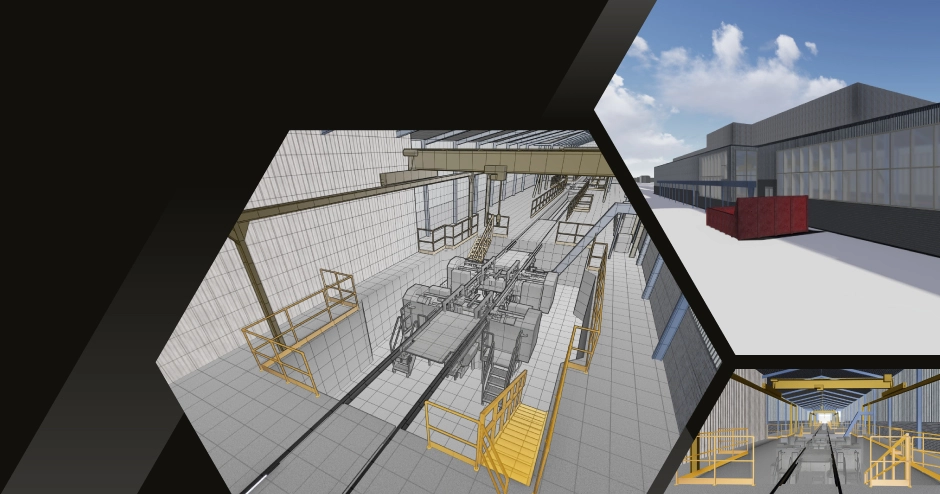

FEATURED PROJECT

Illford Wheel Lathe Feasibility Study

DESCRIPTION

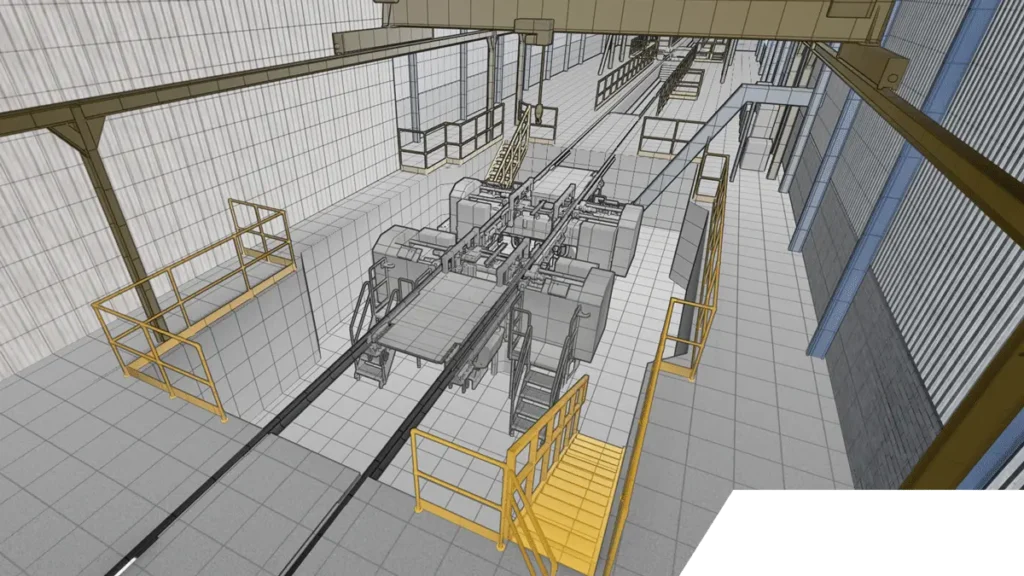

The project involved the replacement of a life-expired single-headed wheel lathe with a new double-headed wheel lathe capable of accommodating both 4-car and 5-car sets across a range of rolling stock fleets.

The objective was to enhance maintenance capability, improve operational efficiency, and ensure long term resilience of the facility.

Hexagon Design was appointed to provide consultancy support throughout the early project stages, undertaking a structured optioneering process to identify the optimum location for the new double-headed wheel lathe within the existing depot environment. The scope included reviewing existing infrastructure and assets to confirm their suitability for the proposed upgrade, while identifying any modifications required to enable safe and compliant installation.

All designs and assessments were developed in line with Network Rail standards and in accordance with the GRIP process, ensuring full compliance and alignment with industry best practice.

REQUIREMENTS

Hexagon provided a full design solution covering all critical aspects required for the successful integration of the new system, including:

- Optioneering to determine the optimum location for the double-headed wheel lathe

- Identification of required alterations to:

- Building structures

- Infrastructure and permanent way

- Foundations and wheel lathe pit

- Overhead Line Equipment (OLE)

- Assessment of the suitability of the existing crane for installation and maintenance activities

- Verification of existing power supply capacity to support the new wheel lathe

- Production of Network Rail–compliant designs in accordance with the GRIP process

- Ground Penetrating Radar (GPR) survey to identify existing services

- Desktop studies including:

- Gauging assessments

- Crane suitability

- Existing infrastructure dimensions

- Rolling stock clearances

- Site investigations to assess the condition of:

- Building steelwork

- Concrete wheel lathe pit

- Permanent way

- Preparation of outline drawings

- Development of a feasibility report

- Production of 3D visualisations and fly-throughs to support stakeholder engagement and decision-making

- Conducted checks on the depot’s existing power supply capacity

See more projects

Southampton AVIS

Hexagon provided the full design solution for the new AVIS facility under a design-and-construct contract.

Kings Heath AVIS

Hexagon provided the full design solution for the new AVIS facility under a design-and-construct contract.